What Is Industrial Automation?

Automation is a future advancement in mechanization that uses particular human operators for performing particular machinery mechanism for performing a task. The word automation means “self-dictating” or a mechanism move by itself which is derived from Greek. The purpose of it is to make the manual operation of the task using advanced powered machinery that relay on the decision made by a human. It is a useful control system similar to robot or computer and it has information technology for managing different types of machinery and processes in an industry which replace humans. In the scope of industrialization, it is the second step beyond mechanization.Components of Industrial Automation

- Control software

- Control Hardware

- Field instruments

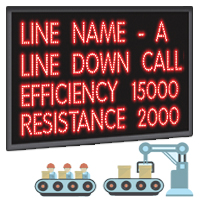

Control software-HMI (Human Machine Interface)

The exchange of information between automated machinery and employees present in the organization is achieved with the help of human-machine interface. The output obtained from the machine is displayed in visual display units or LED display. HMI helps in boosting the productivity. Signals are used as input to control and maintain the automated equipment. HMI makes use of the technology known as SCADA (Supervisory Control and Data Acquisition).Control Hardware- Programmable Logic controller (PLC’s)

The functions of data conversion and handling the signals are provided by the Programmable Logic controller. It helps in controlling the manufacturing process and machinery assembly lines. The important module in it is microprocessors which can be programmed repeatedly. Others include I/O modules (both Digital and Analog) which are used to connect the various input and output module devices and relay modules.Sensors- field instruments

The sensors detect the change in physical parameter and convert it into equivalent input signals The change in the environment may be humidity, pressure, force, liquid flow and these changes will be converted into input signals.Advantages of Industrial Automation

Lower operating cost

When the company have human operators it comes around the situation such health care costs, paid leave, holidays and even employee benefits like bonuses, pension coverage etc. Industrial automation helps to overcome these problems, though it is associated with initial high cost but we can overcome monthly wages of the workers which makes a company to have substantial cost savings for the company. The machine does not often fail hence the maintenance charge associated with machinery is less and only technical engineers or maintenance are required to repair it.High productivity

Nowadays many companies recruit many employee and production workers for up to three shifts to keep running the plant for 24 hours but due to holidays and strikes the plant need to be closed. The concept of industrial automation helps to achieve the target of the company in holidays and also for 24/7 working hours without closing the types of machinery. This leads to significant improvement in the productivity of the company.High Quality

As we know that the humans cannot be ideal in case of the error associated with them. Robots used in the industries are 100% accurate and which results in uniformity of the Products obtained in all different times.High flexibility

If there is up-gradation in Centralized Software and hardware the employees need a training which Requires some time and creates delay but with help of robot they can be programmed this Process more flexible.High Information Accuracy

By adding an automated data collection it allows you to improve data accuracy, reduced data collection costs and collect key production information by this the operator can make a right decision with accuracy and here will be no wastage of time.

High Safety

By developing an automated robot production line can safer for employees to handle the hazardous condition.

The disadvantage of Industrial Automation

The initial investment requires huge investment because the sudden switch from humans to a robot in an automated production line is very high. And some investment is required is to train even the employees to handle new machinery.

Conclusion

Because of its huge benefits the industrial automation as finding more and more applications such as safety at low costs, increased productivity, etc.

0 Comments