Industry 4.0

The concept of Industry 4.0 is related to the manufacturing

industry mainly where machines get automated for production. Industry 4.0 not

only improves the efficiency in machinery but also increases efficiency in

people. How?, let’s see

When machines get automatic in their process, then human

workers don’t need to spend time on machines like keeping watch on production

line, defective products, packaging etc. They can manage their time in other

tasks.

What exactly is Fourth Industrial Revolution?

Companies use advent of mechanism of steam power and water

power in the First Industrial Revolution

Mass production was introduced in the Second Industrial

Revolution with the help of Electricity.

Companies got more advanced by using electricity, IT system,

and little automation in machines in Third Industrial Revolution.

And now, Companies have started to connect cyber system with

machines where no human intervention is required thus making the factories

smart and this is the Fourth Industrial Revolution.

How Industry 4.0 Works?

There are components in industry 4.0 that make factories

smart. Industry 4.0 is not just one concept, it’s a concept that started from

first industrial revolution.

Let’s dig a little deeper!

The major thing for industries is how factories can be

effective in their processes. And in the focus of this point, every

manufacturer finds various ways to make it better. In such a way by continuous

brain storming the industrial revolution takes place each decade.

The Fourth Industrial Revolution is related to digital

technology which makes things better to manage, maintain and measure. The human

actions reduce in manufacturing process. Machine to machine communication and

internet of things atomizes the whole system.

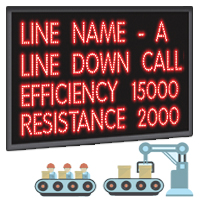

Machines get coded with specific tasks with a unique

Identifier and it gives all required information related production by its own.

Information flow gets easy as each machine has unique identifier.

Automation brings inter connectivity between processes,

communication and technical assistance making it a centralized process.

In short, fourth industrial revolution allow machines to get

automated in manufacturing for more efficiency.

How industry 4.0 will change the following things?

Excuses for work:

Machines will not give any excuses in

working hours. Such as I need to go to hospital so I need to leave early today.

It’s not my work, tell someone else:

This is major issue in

human operated tasks. Operator can assign different tasks to machines. And

machines will not say, “it’s not my work, tell someone else”.

Salary first:

Machines will work without salary. But yes, it

needs maintenance.

In this salary, only this much work:

Machines will keep on

working with efficiency for 24/7 without asking for monthly salary. It is

one-time investment.

Increased working hours:

as machines will keep doing the

work without any error in production process and will not take any leave, the

total working hours will automatically increase.

Three things will be improved in manufacturing process

Communication:

communication between operator and engineers,

between different departments, between machinery will improve.

Decision Making:

effective communication is the major thing

which helps to make effective decision. And if communication will improve then

decision making process will also improve.

Production Efficiency:

proper communication and decisions makes production efficient.

.png)

1 Comments

Nice presentation.

ReplyDelete