How to Improve Productivity in Manufacturing

This is the century of competition. If you want to be a

market leader, you have to be fast and innovative to fulfill customer's demand.

Companies keep innovating their products somehow to increase sell. But the

supply of products according to demand is also equally important as

innovation.

For that manufacturer must be fast and quick in their

manufacturing. Because if there is a delay in manufacturing, supply chain will

also get delayed. So, here are the ways to improve productivity in

manufacturing.

Six ways to improve productivity in manufacturing.

Existing Workforce Assessment

Manufacturers must analyze existing workforce, which are in

use for production. There are two types of workforce in manufacturing,

- People: need to look who is doing what task on the production floor. Is he/she doing the job better? How efficiently he/she is adopting new things? How accurate is his/her work. Such kind of assessment is required for people workforce.

- Machine and equipment: need to look for machine quality, depreciation, replacement parts, etc. Because machine should be in good condition during the production process. Otherwise, unwanted accident can take place on the production floor.

So, the manufacturer should analyze the existing workforce for

better productivity. The Manufacturer should understand the requirement of

production in 360 degrees because any change also have the cost linked to

it.

Upgrade Technology and Processes

Technology is now very important in every business. Whether

it is small or big. There was a time

where people were very important asset for manufacturers but now it is the time

where latest machines and equipment are very important assets more than

people.

Manufacturer need to understand the requirement of market as

every week market demands and customer’s need change because of heavy of

competition in the market. Manufacturer has to be accurate and fast in every

aspect. And this can be possible only through upgrading technology and old

processes.

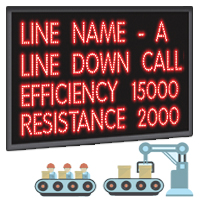

Prevent Unplanned Downtime

This is the common and major issue that most of the

manufacturers face in production. Unplanned downtime happens during production

process due to some machine or equipment fault/failure. If production line is

big then lot of time gets spent in just identifying the exact issue in

production line.

This issue can be prevented permanently. “ANDON System” can

help you prevent unwanted downtime in production line. The aim of this system

is to give alert when some problem arises

It also sends alert to specific people working on production line

through emails/ANDON light/sound.

Educate Workers about Technology

Suppose you are manufacturer and you take care of all the

things related to production. You install latest technology for production to

get better and efficient but it will be of no use if your workforce does not

know how to use them.

Educating workforce frequently and efficiently is of prime

importance.

Some companies do have this problem where the workers do not

have enough knowledge to operate the latest machine and the company does not

even conduct a training program for them. It is very important, because at the

end, it is up to the man to operate the machine.

Organize Workspace

Organize workspace in such a way that makes things easy on

production floor. It’s not about machine. One can adopt following ways,

- Find a way to reduce movement on the floor

- Remove unnecessary tools and materials from workspace

- Create cupboard for tools which will save time wasted to look for the right item

- Create organized storage spaces for miscellaneous things

This will also help in creating healthy work environment on

production floor. Workers need to be calm while working and organized workplace

helps in many way.

Make Accurate Data Tracking System

One major thing in improving productivity is accurate data

and reports. If management have accurate report of manufacturing, then it will

help in better decision making. And again, for this, manufacturer need to

install latest technology and equipment which provides real time data such as

total production, total working hours, total downtime, machine breakdown

etc.

Accurate data shows where and how much work needs to be

done. So accurate data tracking also help in improving productivity in

manufacturing.

Manufacturing Execution System based Production Monitoring System could be the excellent solution for accurate data tracking. The MES software provides a dashboard which captures real time data from factory floor and could be accessed anytime anywhere.

.png)

0 Comments