Introduction To Production Monitoring System

Production Monitoring means an on-site Product Inspection performed every day ofyour production. An inspector scrutinizes your factory, enforcing your specifications,

selecting units at random for inspection and identifying and eliminating defects. You receive

daily reports regarding quality and completion status, putting you in control of the entire

process.

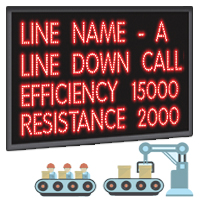

The main reason for implementing PMS (Production Monitoring Systems) is to

analyze real-time Production Monitoring and to offer better solutions for all scale production

companies. PMS is an alternative to manual data collection and should capture most of the

required production data without human intervention. It is a production tool that collects and

distributes necessary data when various events occur in a station or production line.

Monitored data should help the production team to respond timely to the events that may

affect the desired result. Such system should also alarm and inform respective department

concerning all recognized faults. PMS is not just displaying boards that show production data, it

also has a reporting and administration module, where stored data can be analyzed to find

trends, estimations, and projections for easier decision making and production planning.

The benefits of installing an effective and efficient real-time PMS is the immediate on-screen access to all production related information. Besides relevant production

information’s, the system also helps various level of people in industries to optimize their

performance by all means.

Some main advantages of going to Production Monitoring System:-

- It reduces setup times

- Deliver real-time information

- Increase production capacity

- Increase production efficiency

- Targeted and performance-based

- Improve customer service

- Real-time visualization of production status and performance

- Transparency in production status to ease production planning and scheduling

0 Comments