Introduction

In the year of 2020, there was many challenges for everyone.

That year was disaster for everyone be it a businessman or jobber. If we talk

about business, every sector was affected but the manufacturing industry

affected the most during the pandemic year.

With the start of 2021, every business started hoping for

the best especially manufacturing industry. To grab opportunities for your

business you need to know the trends in manufacturing industry. This can help

your business speed up to get back and running.

Trends that boost manufacturing industry in 2021

Employee's health and safety

Employee's health and safety is always the matter of focus

for all industries. And some improvements are taking place with time. Like safety

shoes, safety goggles, jackets etc. were made mandatory.

It’s good that companies provide internal safety components

but that’s not enough. Apart from this, some measurable things need to be

brought to notice. There is data of who get injured, but there is no accurate

data of why someone got injured, in which department, on which time, how many,

etc.

So why these things should be included in employees' health

and safety? Because there is one simple reason that if data related to these

things are stored. Then companies will get to know the actual reason of injury

of each and every employee and it can be controlled.

Installing Health and Safety Display Board to track accurate

data is one solution which companies can adopt as it is also mandatory by government.

Smart Manufacturing

What if machines let operators and engineers know about the

problem? Yes, in today’s industry 4.0 world, it is possible.

Now a days, machines get automated in their process.

Internet of Things has made it possible for machines to talk with

machines.

If you are a manufacturer then you should be aware about the

issues in your factory facility like production breakdown, downtime, total

operating hours etc. Knowing the issue at the earliest and solving it in less

time will reduce the downtime.

When issue related to machine arises, normally it takes

longer time to just identify the issue. Because this is manual process where operator

finds the problem, and then inform concerned operator/engineer about it and

then it gets solved. This is a very lengthy process and very time consuming

too. Due to more consumption of time the productivity and efficiency decreases

as it results in waste of manpower hours.

This is the reason why manufacturing process could not run as smooth as

expected.

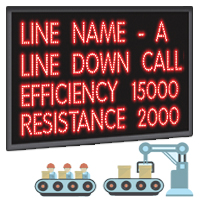

ANDON system solves this problem. ANDON system is a great

example of Smart Manufacturing Unit. It identifies the issue and notifies to

concerned department in no time. It also records the downtime and communicates

it to management via SMS or Email in real time for them to take action

immediately, if it does not get solved in ideal downtime.

Digital Connectivity

Digital Connectivity make machines smarter. Digital

connectivity between object, system and application makes things easy. When

machine operates through Industrial Internet of things (IIOT), it will get more

intelligent and efficient and ideas will get real.

Great example of digital connectivity is production

monitoring system. Many companies are already using Production monitoring

system for tracing their production data in real time.

It not only tracks target, actual and gap in the production

but also generates MIS reports. Production Monitoring System when integrated

with MES (Manufacturing Execution System) the live dashboard is available which

calculates the efficiency of the production line and most importantly it

calculates the OEE which is must for each manufacturer for better planning and

take decisions.

Operate Green in Manufacturing

Pollution through production is the concern from starting of

industrialization till now. Pollution has increased to such an extent that

government is also now concerned and has formed strict pollution rules for

manufacturing industries.

Whether or not each factory is following guidelines,

government and even top management of company need to stay aware. For this,

installing Pollution parameter display, Safety Parameter display and Environmental,Health and Safety display is the best resort.

The digital display of each parameter on single screen makes

it easy for manufacturing unit to stay updated. It not only displays data but

can also feed real time data directly from machines or government portal.

Front line Employees

Let’s talk about trend related to employees. Employees and

workers are the main and important asset of each company. Company needs to take

care of its employees. Many companies offer different benefits so that

employees can keep record of their work and time.

But wait, that’s not enough, there also comes responsibility

from employees' side as well. If employees and workers are not punctual and if

the management cannot record their impunctuality it results in

inefficiency.

With the advanced technology companies can have time attendance management system which manages attendance of employees with

automation, records time, apply leave and track their daily punch in and punch

out time. The manager and HR both stays aware and can easily tracks and analyze

the automatic generated reports at fingertips.

Trends will keep on changing with time but main thing is how

industries adopt changes. Big companies always upgrade themselves with the

trend. Because changes bring development and trends are meant for advancing.

And this is the Trend of Automation. Upgrade your business with Technology

2 Comments

It is good article. Well written

ReplyDeleteThank you RP

Delete